Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Oct 8, 2014 2:03:42 GMT

Im about to fit new rings and as you know you cant use a conventional ring clamp.What's the best way to get the barrels onto the pistons, any tips. Also when I stripped it none of the head bolts had any seals on them, is this correct, is it year dependant. Its a 1980 400. Thanks in advance Mark.

|

|

|

|

Post by stevie on Oct 8, 2014 9:11:12 GMT

Suki my mate and i did a piston each just using our fingers to sqeeze the rings together, was going to cut a cola tin to make some strips to compress the rings but didnt need to in the end, good luck

|

|

|

|

Post by rich on Oct 8, 2014 9:12:45 GMT

hi suki,

is the engine in the frame, or out?

if out, is the crankcase assembled just needing the barrels and head fitting?

if not yet assembled, with the rods fitted to the pistons the correct way round ( rod oil holes to rear of engine ) and the rings fitted correctly ( top ring is chromed, has a "T" for top, the second ring is not chromed and may have an "N" for second and fitted uppermost ) and the oil control ring ( single or 3 piece?? ) fitted in the ring slot of that size...........if 3 piece then fit the expander first, then one rail then the other, paying attention to ends and butts, the expander must be "butted" correctly and not "overlap"........

I assume the piston is clean as well as the ring grooves..........

if new rings, be aware of the "wear ridge" at the top of the cylinder bore, new rings will "Crash" into this and break if not attended to........

rings spaced as per diagram ( they do rotate when engine running but that's how Honda want them fitted, they know best! ) .........

fit the pistons to the barrel on the bench, which is easy as you deal with them one at a time, then fit the barrel "unit" to the upper crank case and hold in place with a suitable bolts or studs......that is how it was done in the factory I believe............make sure the base gasket is all ok ( oil holes ) and that the jets are in the right way round, tubes down, chamfers up.......you attended to the cyl base "slots" and the head bolt holes are absolutely clean all the way down to there bottoms........10mm x 1.25 pitch from memory.....

there are some piston ring clamps out there, pliers type........or some suitable drain pipe cut to length and slitted to pass the rod...........else they are fitted VERY CAREFULLY........both at the same time! |

|

|

|

Post by rich on Oct 8, 2014 9:14:24 GMT

as above with a mate and probes, steady as you go.........blocks under the cyl base to set the height for easy and safe ( for the rings ) fitting........

|

|

|

|

Post by grahamb on Oct 8, 2014 11:26:19 GMT

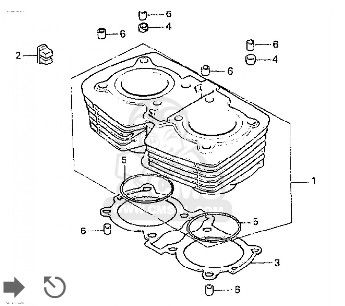

when I stripped it none of the head bolts had any seals on them, is this correct, is it year dependant. Its a 1980 400. Thanks in advance Mark. Hi Mark The 2 rear outer head bolt should have seals between the head and barrels . the 4 inner head bolt should also have copper washer(seals) under the head of the bolt. number 4 on diagram.  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Oct 8, 2014 18:02:11 GMT

Thanks for all your replies, I will be putting the barrels onto the rods and pistons as the rest of the engine is untouched. The only reason for the strip down was an oil leak at the rear of the barrels so while its down Im fitting new rings as old rings tend to be even more brittle and its not good practice anyway. The bores are as good as gold, so a quick session with a glaze buster should be ample. Again thanks for your replies. Mark.

|

|

|

|

Post by garethp on Mar 5, 2016 21:49:50 GMT

Hi

DId you manage to fit the pistons into the barrels?

I am at the exact same stage you was at. I've just tried to fit them and ive only gone and snapped a ring. I think i may have to dissasemble from the crank and fit the pistons into the barrels on the bench instead of trying to slide it over the both of them and risk snapping another ring.

How easy is it to get at the crank to disconnect to conrod?

Thanks

Gareth

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 5, 2016 21:55:20 GMT

Suki is no longer an active member here Gareth.

If anyone else can help Gareth with his question, please do.

|

|

|

|

Post by garethp on Mar 5, 2016 22:01:27 GMT

Thanks for the heads-up.

|

|

|

|

Post by mikef on Mar 5, 2016 23:44:18 GMT

|

|

|

|

Post by garethp on Mar 6, 2016 8:20:12 GMT

Hi Mike.

I took the plunge last night and ordered 2 ring clamp sets after watching a video on YouTube. They are for motorcycles so I hope they will be a smaller depth than a car type.

Did you manage to fit the barrels over the pistons with them all connected to the crank or did you separate them and fit into the barrel first then connect onto the crank?

I'll wait for these and the new piston rings from David Silvers to turn up and I'll let you all know how it goes.

Thanks.

|

|

|

|

Post by mikef on Mar 6, 2016 14:46:35 GMT

Hi Gareth.

The pistons were still connected to the crank. I just smeared the pistons with oil, fitted the compressors until the rings were fully compressed into the piston grooves, just tight enough to allow the pistons to still slide in the compressors. and then put the barrel over the pistons and tapped it down with a nylon headed mallet. When the rings were fully inserted into the barrels I removed the compressors.

It was much easier than I thought it would be. I think the important thing is tightening the compressors enough to fully compress the rings, but loose enough to allow the compressors to slide down the pistons as the block is tapped down.

Hope that makes sense.

Oh, and don't forget to put the base gasket on first.

Mike.

|

|

|

|

Post by garethp on Mar 6, 2016 14:53:37 GMT

Cheers for the tips.

I'll let you all know next week when the turn up

|

|